We engineer, manufacture and market Threaded Tee and high nickel alloys.

We manufacture & export world-class performance Threaded Tee

-

Type of Threaded Fittings

- Elbow

- Elbow 45°

- Elbow 90°

- Threaded street elbow

- Tee

- Threaded Tee

- Cross

- Threaded cross

- Coupling

- Threaded full coupling

- Threaded half coupling

- Cap

- Pipe Cap

- Threaded pipe cap

- Union

- Threaded Union

- Threaded lateral tee

- Nipple

- Hex nipple

- Threaded nipple -type A

- Threaded nipple -type B

- Threaded nipple -type C

- Swage nipples

- Threaded pipe fittings

- Hex Head Bushings

- Plugs

- square head plug

- hex head plug

- Round head plug

Threaded Tee is a type of pipe fitting is defined as a part used in a piping system, Welding a fitting to the pipe means it is permanently leakproof. We are a largest pipe fitting manufacturer for all type of industries in India & shipping worldwide. We can manufacture all 3 groups of Fittings such as Buttweld (BW) fittings, Socket Weld (SW) fittings & Threaded (THD) fittings as per ASME B16.11 standards & other International standards. Specialized in 45 degree elbow, 90 degree elbow, 180 degree elbow, concentric reducer, eccentric reducer, straight tee, equal tee, reducing tee, Y tee, cross, lap joint stub end, pipe cap, blind flange, slip-on neck flange, butt-welding neck flange, flat flange. Metal-Tech Engineers continues to meet customers’ needs through global quality standards from original design to distribution. Metal-Tech Engineers manufactures to global standards.

We are one of the leading importer, stockholder, suppliers & exporters dealing in Threaded Tee since 1990. When procuring raw materials to manufacture Threaded Tee, our primary responsibility is to ensure that same quality and consistency exists in our supply base.

Threaded Tee Specification

Stainless Steel Threaded Tee | Carbon Steel Threaded Tee | Nickel Alloys Threaded Tee | Monel Threaded Tee | Alloy Steel Threaded Tee | Mild Steel Threaded Tee

Size: NPS ½" through 4" Pressure Class: 2000#, 3000#, 6000#, 9000#, 10000#

End: Threaded and Socket Weld

Type: Coupling, ½ Coupling, Reducing Coupling, F/F Union, Branch Reducing Tee, Straight Tee, 45° Elbow, 90° Elbow, 90° Street Elbow, Hex Bushing, Hex Plug, Cap

Material: ASTM A105N (Black and Galvanized), ASTM A350 LF2, ASTM A182 F5, ASTM A182 F9, ASTM A182 F11, ASTM A182 F22

Specifications: ASME: B16.11, MSS: SP.83

Special Items: Solid Tee, Solid Branch Tee, Round Head Plug, Cross, SW Insert

-

Other grades or sizes may be available upon request.

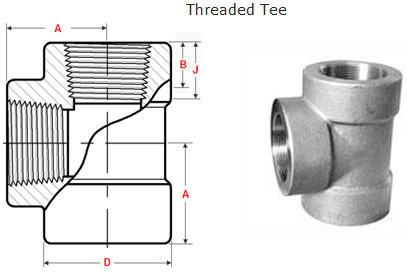

Threaded Tee Dimensions

Dimensions threaded Tee - NPS 1/2 to 4 - 2000 LBS - ASME B16.11

| NPS | Minimum Length of Thread |

Outside Diameter of Band D |

Center to End A |

Minimum Wall Thickness |

|

|---|---|---|---|---|---|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1¼ | 17 | 18 | 56 | 44 | 3.89 |

| 1½ | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2½ | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Dimensions threaded Tee - NPS 1/2 to 4 - 3000 LBS -

| NPS | Minimum Length of Thread |

Outside Diameter of Band D |

Center to End A |

Minimum Wall Thickness |

|

|---|---|---|---|---|---|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1¼ | 17 | 18 | 62 | 51 | 5.28 |

| 1½ | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2½ | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

Dimensions threaded Tee - NPS 1/2 to 4 - 6000 LBS - ASME B16.11

| NPS | Minimum Length of Thread |

Outside Diameter of Band D |

Center to End A |

Minimum Wall Thickness |

|

|---|---|---|---|---|---|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1¼ | 17 | 18 | 75 | 60 | 10.59 |

| 1½ | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2½ | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

General notes:

- Dimensions are in millimeters unless otherwise indicated.

- Dimension B is minimum length of perfect thread.

The length of useful thread (B plus threads with fully formed roots and flat crests) shall not be less than J.

Threaded Tee Packaging

Package details: Each order is packaged according to the customer’s standards including preparation for export such as wooden case, pallet or according to customer's requirement

All shipping documentation is provided for seamless delivery from mill to customer.

We export to:

Threaded Tee exporter, manufacturer & suppliers in Dubai, Saudi Arabia, Qatar, West Africa, Russia, Kuwait etc.

ASTM Grades

| Material | Fittings | Flanges |

|---|---|---|

| Carbon Steel | A234 Gr WPA |

A105 |

A234 Gr WPB |

A105 |

|

A234 Gr WPC |

A105 |

|

| Carbon Steel Alloy High-Temp |

A234 Gr WP1 |

A182 Gr F1 |

A234 Gr WP11 |

A182 Gr F11 |

|

A234 Gr WP12 |

A182 Gr F12 |

|

A234 Gr WP22 |

A182 Gr F22 |

|

A234 Gr WP5 |

A182 Gr F5 |

|

A234 Gr WP9 |

A182 Gr F9 |

|

| Carbon Steel Alloy Low-Temp |

A420 Gr WPL6 |

A350 Gr LF2 |

A420 Gr WPL3 |

A350 Gr LF3 |

|

| Austenitic Stainless Steel |

A403 Gr WP304 |

A182 Gr F304 |

A403 Gr WP316 |

A182 Gr F316 |

|

A403 Gr WP321 |

A182 Gr F321 |

|

A403 Gr WP347 |

A182 Gr F347 |

Fittings

- A234 = This specification covers wrought carbon steel and alloy steel fittings of seamless and welded construction.

- A420 = Standard specification for piping fittings of wrought carbon steel and alloy steel for low-temperature service.

- A403 = Standard specification for wrought austenitic stainless steel piping fittings.

Flanges

- A105 = This specification covers standards for forged carbon steel piping components, that is, flanges, fittings, Valves, and similar parts, for use in pressure systems at ambient and higher-temperature service conditions.

- A182 = This specification covers forged or rolled alloy and stainless steel pipe flanges, forged fittings, and Valves and parts for high-temperature service.

- A350 = This specification covers several grades of carbon and low alloy steel forged or ring-rolled flanges, forged fittings and Valves for low-temperature service.

Products

- Flange

- Buttweld Fittings

- Forged Fitting-Thread Fittings

Elbow

Elbow 45°

Elbow 90°

Threaded street elbow

Tee

Threaded Tee

Cross

Threaded cross

Coupling

Threaded full coupling

Threaded half coupling

Cap

Pipe Cap

Threaded pipe cap

Union

Threaded Union

Threaded lateral tee

Nipple

Hex nipple

Threaded nipple -type A

Threaded nipple -type B

Threaded nipple -type C

Swage nipples

Threaded pipe fittings

Hex Head Bushings

Plugs

square head plug

hex head plug

Round head plug - Forged Fitting-Socket weld Fittings

01. Buttweld (BW) fittings

Carbon Steel Section -

- Elbow 90° long radius

- Elbow 45°

- Elbow 90° short radius

- Elbow 180° long radius

- Elbow 180° short radius

- Tee straight

- Tee reducing

- Reducer concentric

- Reducer eccentric

- Buttweld-Cross

- Buttweld Cap

- Buttweld lateral tee

- Carbon steel straight cross

- Carbon steel reducing cross

Stainless Section -

03. Threaded (THD) fittings

- Elbow

- Elbow 45°

- Elbow 90°

- Threaded street elbow

- Tee

- Threaded Tee

- Cross

- Threaded cross

- Coupling

- Threaded full coupling

- Threaded half coupling

- Cap

- Pipe Cap

- Threaded pipe cap

- Union

- Threaded Union

- Threaded lateral tee

- Nipple

- Hex nipple

- Threaded nipple -type A

- Threaded nipple -type B

- Threaded nipple -type C

- Swage nipples

- Threaded pipe fittings

- Hex Head Bushings

- Plugs

- square head plug

- hex head plug

- Round head plug

AN ISO 9001:2008 Certified Company