We engineer, manufacture and market Slip-On Flange and high nickel alloys.

We manufacture & export world-class performance Slip-On Flange

-

Type of Flanges

- Welding Neck Flange

- Blind Flange

- Slip-On Flange

- Socket Weld Flange

- Lap Joint Flange

- Threaded Flange

- Reducing Flanges

- Spectacle Blinds

- Spades and Ring Spacers

- Square Flange

- Orifice Flanges

- RTJ Flanges

Slip-On Flange produced in our Mumbai factory, carries a promise of quality and consistency. Metal-Tech Engineers continues to meet customers’ needs through global quality standards from original design to distribution. Metal-Tech Engineers manufactures to global standards. We are one of the leading importer, stockholder, suppliers & exporters dealing in Slip-On Flange since 1990. When procuring raw materials to manufacture Slip-On Flange, our primary responsibility is to ensure that same quality and consistency exists in our supply base.

Metal Tech is excellently equipped for the production of tailor-made, high-grade flanges. In our forging shop, an advanced, automatically controlled steel bar furnace with a length of over 12 m heats the raw material up to approx. 1,100°C before rings or flanges with an outside diameter of up to 2,800 mm are formed using our face plate bending machine.

Slip-On Flange Specification

Stainless Steel Slip-On Flange | Carbon Steel Slip-On Flange | Nickel Alloys Slip-On Flange

Standards: ANSI, BS4504, EN1092-1/12, ANSI, ASME, ASA B16.5, SORF

Model: SLIP ON FLANGE, SORF FLANGE, SOFF FLANGE

Size: 1/2” - 48”

Process: Forged, Forging

Packing: Plywood Pallets

Also see related products:

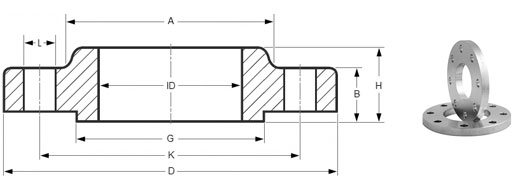

Slip-On Flange Dimensions and Tolerances

Dimensions Slip On Flange ASME B16.5

| Class | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

| Diameter - A | 30 | 38 | 38 | 38 | 38 | 38 | ... |

| Diameter - D | 90 | 95 | 95 | 95 | 120 | 120 | ... |

| Thickness - B | 9.6 | 12.7 | 14.3 | 14.3 | 22.3 | 22.3 | ... |

| 11.2 | 14.3 | 20.7 | 20.7 | 28.7 | 28.7 | ... | |

| Diameter - G | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | ... |

| Diameter - K | 60.3 | 66.7 | 66.7 | 66.7 | 82.6 | 82.6 | ... |

| Height - H | 14 | 21 | 22 | 22 | 32 | 32 | ... |

| 15.6 | 22.6 | 28.4 | 28.4 | 38.4 | 38.4 | ... | |

| Bolt Holes | 4 | 4 | 4 | 4 | 4 | 4 | ... |

| Diameter - L | 15.9 | 15.9 | 15.9 | 15.9 | 22.2 | 22.2 | ... |

| Stud Bolts Diameter x Length | |||||||

| Diameter (in) | 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | ... |

| Length (mm) | 55 | 65 | 75 | 75 | 110 | 110 | ... |

| 1/2 | 3/4 | 1 | 1¼ | 1½ | 2 | 2½ | 3 | 3½ | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

--------------------------------------------------------------------------------- > NPS <------------------------------------------------------------------------------

Dimensional Tolerances of Slip On Flanges ASME B16.5

Outside Diameter |

Inside Diameter |

Diameter of Contact Face |

Outside Diameter of Hub |

Diameter of Counterbore |

Drilling |

Thickness |

Length thru Hub |

Notes

1. Dimensions are in millimeters unless otherwise indicated.

2. The length of the stud bolt does not include the height of the chamfers (points).

DIN86029 PN10 Hubbed Slip-on Flange For Welding

DIN86029 PN10 Hubbed Slip-on Flange For Welding in forged steel, Stainless Steel, Carbon steel: C22.8, RST37.2, S235JR, P235GH, P245GH, P250GH, ASTM A105, ASTM A182 F304 (1.4306), F304L(1.4307), F316(1.4404), F316L(1.4404), F321(1.4541) etc.

| Rated Diameter | O.D. of Pipe | Flange Parameter | Neck Size | Size of R.F. | Bolts | Approx. Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | d1 | D | d5 | b | k | h | d3 | r | d4 | f | No. of holes |

d2 | KG |

10 |

17.2 |

90 |

17.7 |

14 |

60 |

20 |

30 |

4 |

40 |

2 |

4 |

14 |

0.56 |

15 |

21.3 |

95 |

22 |

14 |

65 |

20 |

35 |

4 |

45 |

2 |

4 |

14 |

0.62 |

20 |

26.9 |

105 |

27.6 |

16 |

75 |

24 |

45 |

4 |

58 |

2 |

4 |

14 |

0.91 |

25 |

33.7 |

115 |

34.4 |

16 |

85 |

24 |

52 |

5 |

68 |

2 |

4 |

14 |

1.09 |

32 |

42.4 |

140 |

43.1 |

16 |

100 |

26 |

60 |

5 |

78 |

2 |

4 |

18 |

1.58 |

40 |

48.3 |

150 |

49 |

16 |

110 |

26 |

70 |

5 |

88 |

3 |

4 |

18 |

1.76 |

50 |

60.3 |

165 |

61.1 |

18 |

125 |

28 |

85 |

5 |

102 |

3 |

4 |

18 |

2.39 |

65 |

76.1 |

185 |

77.1 |

18 |

145 |

32 |

105 |

5 |

122 |

3 |

4 |

18 |

3.1 |

80 |

88.9 |

200 |

90.3 |

20 |

160 |

34 |

118 |

5 |

138 |

3 |

8 |

18 |

3.77 |

100 |

114.3 |

220 |

115.9 |

20 |

180 |

38 |

140 |

5 |

158 |

3 |

8 |

18 |

4.29 |

125 |

139.7 |

250 |

141.6 |

22 |

210 |

40 |

168 |

5 |

188 |

3 |

8 |

18 |

5.86 |

150 |

168.3 |

285 |

170.5 |

22 |

240 |

44 |

196 |

5 |

212 |

3 |

8 |

22 |

7.22 |

175 |

193.7 |

315 |

196.1 |

24 |

270 |

44 |

224 |

6 |

242 |

3 |

8 |

22 |

9.18 |

200 |

219.4 |

340 |

222 |

24 |

295 |

44 |

247 |

6 |

268 |

3 |

8 |

22 |

9.95 |

250 |

273 |

395 |

276 |

26 |

350 |

46 |

300 |

6 |

320 |

3 |

12 |

22 |

12.69 |

300 |

323.9 |

445 |

327 |

26 |

400 |

46 |

352 |

6 |

370 |

4 |

12 |

22 |

14.4 |

350 |

355.6 |

505 |

359 |

26 |

460 |

53 |

398 |

10 |

430 |

4 |

16 |

22 |

22.36 |

400 |

406.4 |

565 |

410 |

26 |

515 |

57 |

448 |

10 |

482 |

4 |

16 |

26 |

26.85 |

450 |

457 |

615 |

461 |

28 |

565 |

62 |

502 |

10 |

532 |

4 |

20 |

26 |

32.53 |

500 |

508 |

670 |

512 |

28 |

620 |

67 |

552 |

10 |

585 |

4 |

20 |

26 |

37.84 |

600 |

610 |

780 |

614 |

28 |

725 |

75 |

658 |

10 |

685 |

5 |

20 |

30 |

49.32 |

700 |

711 |

895 |

716 |

30 |

840 |

77 |

760 |

10 |

800 |

5 |

24 |

30 |

63.86 |

800 |

813 |

1015 |

818 |

32 |

950 |

84 |

864 |

10 |

905 |

5 |

24 |

33 |

85.19 |

900 |

914 |

1115 |

920 |

34 |

1050 |

88 |

969 |

10 |

1005 |

5 |

28 |

33 |

101.4 |

1000 |

1016 |

1230 |

1022 |

34 |

1160 |

92 |

1071 |

10 |

1110 |

5 |

28 |

36 |

119.7 |

Slip-On Flange Packaging

Package details: wooden case, pallet or according to customer's requirement

We export to:

Exporter & Suppliers of Slip-On Flange in Dubai, Saudi Arabia, Qatar, West Africa, Russia, Kuwait etc.

Slip-On Flange Materials

Products

Why choose Us?

01. Quality Management

EXCEL quality management system is as per the National & International standards. Our manufacturing quality is consistently higher than industry specifications...

02. Commitment to complete customer satisfaction

The customer is at the center of everything we do. Complete customer satisfaction - in terms of products, services and punctuality - is our bottom line...

03. We strive to be the best in our industry.

Price

- ASME B16.5 Welding Neck Flange

FOB Price: US $1-2000 / Ton - Blind Flange

FOB Price: US $1-100 / Piece - Slip-On FLANGE ANSI B16.5 150CLASS

FOB Price: US $10-1000 / Unit - socket weld rf flange

FOB Price: US $0.5-200 / Piece - ansi b16.5 150lb socket welding flange

FOB Price: US $100-9999999 / Ton - Lap joint flange

FOB Price: US $780-2650 / Ton - threaded flange

FOB Price: US $1-1000 / Piece - ASME B16.5 Reducing Flange

FOB Price: US $1000-2000 / Ton - spectacle blind B16.48/API590

FOB Price: US $1-5000 / Piece - spade spacer flange

FOB Price: US $1000-2500 / Ton - JIS square flange

FOB Price: US $1-99999 / Piece

- Flange Orifice Plate

FOB Price: US $1500-10000 / Ton - ANSI B16.47 ser"A" (MSS SP 44) A105 Flange 150lb rtj flanges

FOB Price: US $1.2-100 / Piece - ASME B16.5 SW Flange RTJ

FOB Price: US $1500-10000 / Ton

AN ISO 9001:2008 Certified Company